The advantages of Sinoroader bitumen decanter equipment over similar domestic equipment are reflected in the following points:

1. The equipment produces 8-10t/hour, with an automatic telescopic sealed container structure. It uses an electric hoist to lift the asphalt barrel at the inlet guide tube. Start to control the hydraulic cart forward button, which will promote the barrel push (push and slide into the barrel). It is a 1300mm hydraulic cylinder with a 7.5-ton top thrust. The device has a beautiful appearance, reasonable layout, compactness, stable performance, and is suitable for production under various industrial and mining conditions.

2. Fast barrel removal: According to the principle of layered heating, it adopts four-layer thermal oil heating technology, a single inlet and outlet, and high thermal efficiency of heating; at the same time, it uses the waste heat of combustion gas for two heatings and efficient use of energy; the barrel body uses high-quality rock wool insulation material.

3. Good environmental protection: closed structure, no pollution.

4. No barrel hanging: The upper part of the asphalt barrel is hot, and each is directly affected by the thermal oil heating pipe. The barrel wall directly receives the heat dissipation of the heating coil, and the barrel is clean and fast, which will not cause waste of asphalt barrel hanging.

5. Strong adaptability: Suitable for imported and domestic barrels, and the deformation of asphalt barrels will not affect production.

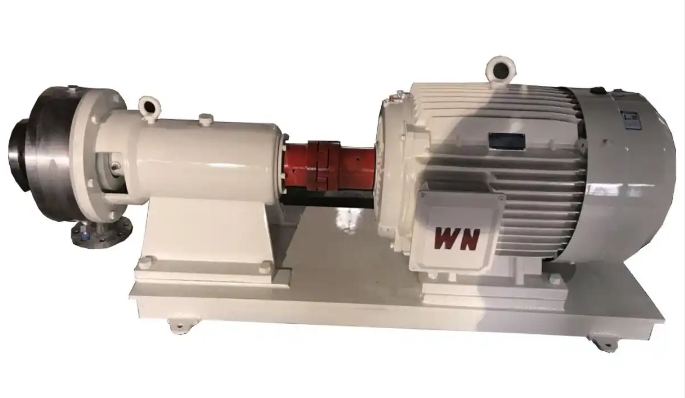

6. Good dehydration: Use a large-displacement asphalt pump for internal circulation, stirring, water vapor overflows, and is naturally discharged from the exhaust port. After dehydration, asphalt can be directly used to produce asphalt mixture or used as matrix asphalt.

7. Automatic slag removal: This set of equipment has an automatic slag removal function. The filter device sets the asphalt circulation pipeline through the filter, which can automatically remove the barreled asphalt slag.

8. Safe and reliable: The equipment adopts an automatic control system, an automatic ignition burner import, can automatically control the temperature according to the temperature, and is equipped with corresponding monitoring instruments.

9. Convenient relocation: The whole machine is assembled with large components, which is easy to move and quick to assemble.