Four major precautions for fog seal layer construction

Fog seal is an asphalt pavement maintenance construction method.

When the asphalt pavement has increased water permeability, loss of fine aggregate, cracks, pitting, etc., a fog seal layer can be used for pavement repair. The bonding material of the fog seal layer is fluid, can repair cracks and gaps, and can heal cracks below 0.3. After construction, the oil content of the road surface is increased, the anti-sticking aggregate is loosened, and it can play a waterproof role.

Before construction, the original road surface should be surveyed and analyzed to determine the construction bonding materials and spray volume.

So what precautions should be taken during construction?

Fog seal is an asphalt pavement maintenance construction method.

When the asphalt pavement has increased water permeability, loss of fine aggregate, cracks, pitting, etc., a fog seal layer can be used for pavement repair. The bonding material of the fog seal layer is fluid, can repair cracks and gaps, and can heal cracks below 0.3. After construction, the oil content of the road surface is increased, the anti-sticking aggregate is loosened, and it can play a waterproof role.

Before construction, the original road surface should be surveyed and analyzed to determine the construction bonding materials and spray volume.

So what precautions should be taken during construction?

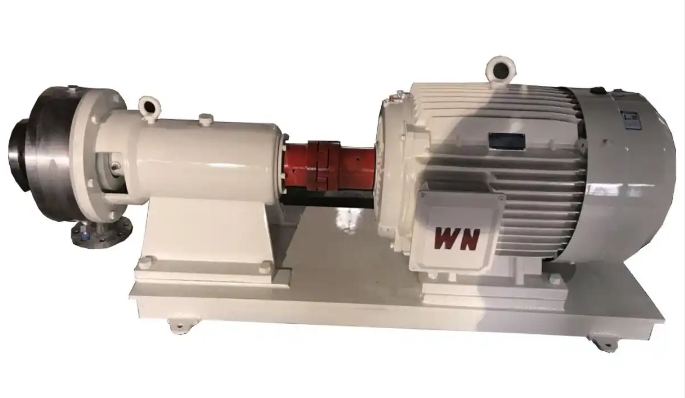

1. In order to ensure the construction effect, a fog seal spray truck or special spray tool should be used to spray the fog seal material according to the set spray rate.

2. For the sake of aesthetics, the spray edges at the starting and ending points of the construction should be neat, and it is advisable to pre-pave linoleum felt at the starting and ending points.

3. During construction, if striped spreading or material leakage occurs, construction should be stopped immediately for inspection. After the problem is found, repair it and continue construction.

4. The construction section needs to be closed for construction. The curing time of the fog seal layer should be determined according to the type of material and climatic conditions, and it can be opened to traffic only after it is dried and formed.

Construction season is coming, are you ready? At this time, you might as well read more and learn more!