How to change the color of asphalt pavement. How to change the color of asphalt pavement?

Changing the color of asphalt pavement is an important project aimed at improving the beauty of roads, optimizing traffic signs and enhancing urban landscape effects. The following is a detailed introduction to the color change of asphalt pavement:

1. Color change method

Using pavement color change spray:

Spray directly on the original asphalt pavement surface to make the road surface look brand new.

This method is simple and fast to construct, with bright and lasting colors, and will not change the structure of the pavement.

Changing the color of asphalt pavement is an important project aimed at improving the beauty of roads, optimizing traffic signs and enhancing urban landscape effects. The following is a detailed introduction to the color change of asphalt pavement:

1. Color change method

Using pavement color change spray:

Spray directly on the original asphalt pavement surface to make the road surface look brand new.

This method is simple and fast to construct, with bright and lasting colors, and will not change the structure of the pavement.

Using colored asphalt technology for paving:

Paving a layer of colored asphalt surface with a thickness of 3~5cm, which is both beautiful and durable.

This method requires professional construction equipment and technology, but the color change effect is long-lasting and is suitable for occasions with high requirements for road performance.

Using colored anti-skid particles for paving:

First pour a layer of anti-skid glue on the road surface, and then sprinkle colored anti-skid particles.

This method not only increases the beauty of the road, but also improves driving safety, especially for occasions that require anti-skid treatment.

2. Color change steps

Preliminary preparation:

Carry out a comprehensive inspection of the original asphalt pavement to ensure that its surface is flat and undamaged, and there are no looseness, cracks and other defects.

If there are quality problems, it is necessary to repair it first to ensure that the color-changing paint can bond well with the base layer.

Cleaning the pavement:

Use a pavement dry cleaner to clean the dust on the original asphalt surface layer, and clean it with water if necessary.

Ensure that the pavement is clean and tidy, providing a good foundation for subsequent color change construction.

Spraying the interface layer:

Use a special primer to spray a construction interface layer on the working surface.

During the construction process, ensure that the foundation is not contaminated, and proceed to the next step of construction after the surface is dry.

Spraying the color layer:

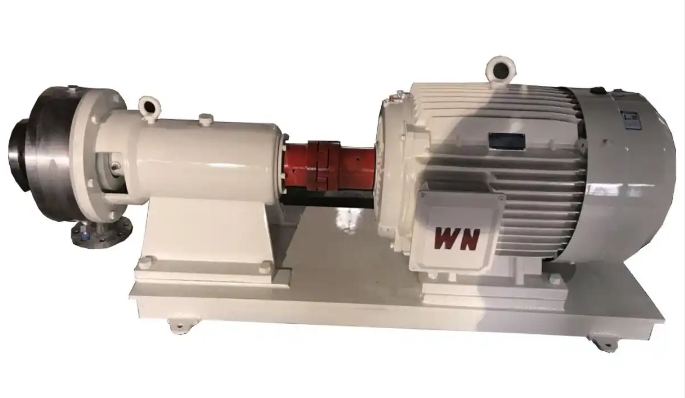

After the interface layer is dry, use an airless sprayer to spray the colored water-based pavement anti-skid paint.

Both sides of the pavement and roadbed should be protected with adhesive tape and plastic film to prevent pollution.

Spraying the protective layer:

To ensure that the finished colored surface layer is bright and lasting, a layer of transparent hydrophobic topcoat can be sprayed after the colored surface layer is sprayed and cured.

This layer of protective agent can effectively improve the aging resistance of colored pavement.

3. Precautions

Material selection:

The color-changing paint should use special colored pavement paint, which is not only bright and long-lasting, but also has good weather resistance, wear resistance and adhesion.

Color design:

The color selection of the pavement color change should consider functionality and aesthetics.

For example, different colors can be used to distinguish the lanes, sidewalks, bus lanes, etc.; at the same time, it should comply with the relevant national regulations on road traffic signs and markings.

Construction process:

Strictly follow the construction process of colored pavement paint.

Including base surface cleaning, primer brushing, color paint coating, surface layer protection and other steps, and ensure that each layer of paint is completely dry before proceeding to the next process.

Environmental protection:

Pay attention to environmental protection during construction to prevent paint from polluting the surrounding environment.

At the same time, the paint itself should have low VOC (volatile organic compounds) characteristics to reduce the impact on air quality.

Safety protection:

Obvious warning signs should be set up at the construction site to ensure the safety of pedestrians and vehicles.

Construction workers need to wear protective equipment to avoid direct contact with chemical paint.

Post-maintenance:

After the color change is completed, regular inspections should be carried out to promptly discover and repair problems such as coating shedding and wear.

To extend the service life of the colored pavement.

In summary, the color change of asphalt pavement is a complex and meticulous project that requires a professional construction team and high-quality color change materials to ensure the color change effect and quality.