The Similarities & Differences Between Drum Mix Asphalt Plant & Continuous Mix Asphalt Plant

Drum mix asphalt plant and continuous mix asphalt plant are two main types of asphalt mixture mass production equipment, which are all widely used in construction engineering, such as harbor, wharf, highway, railway, airport, and bridge building, etc.

These two main types of asphalt plant have similar basic components, for example, cold aggregate supply system, burning system, drying system, mixing system, dust collector, bitumen supply system, and electrical control system. Nevertheless, they differ too much in many aspects as well. This article we will try to introduce the main similarities and differences between the two.

The Similarities Between Drum Mix Asphalt Plant and Continuous Mix Asphalt Plant

Loading cold aggregates into feed bins is the first step in asphalt mixing operation. The equipment typically has 3 to 6 feed bins, and aggregates are put into each bin based on different size. This is done to grade different aggregate sizes according to the project's requirements. Each bin has a belt feeder at the bottom to control the flow of material by frequency regulators. And then the aggregates are collecting and conveyed by a long belt conveyor to the oversize screen for pre-separating.

The screening procedure comes next. This screen removes oversize aggregates and prevents them from entering the drum.

The belt conveyor is critical in the asphalt plant process because it not only transports cold aggregates to the drum but also weighs the aggregates. This conveyor has a load cell that constantly entertains the aggregates and gives a signal to the control panel.

The drying drum constantly rotates, and aggregates are transferred from one end to another during the rotation. The fuel tank stores and delivers fuel to the drum burner. The heat from the burner flame is applied to the aggregates to minimize moisture content.

Pollution control technologies are essential in the process. They aid in the removal of potentially dangerous gases to the environment. The primary dust collector is a cyclone dust collector that works in tandem with the secondary dust collector, which can be either a baghouse filter or a wet dust scrubber.

The ready hot mix asphalt is commonly stored in finished hopper, and finally being discharged into trucks for transportation.

The Differences Between Drum Mix Asphalt Plant and

Continuous Mix Asphalt Plant

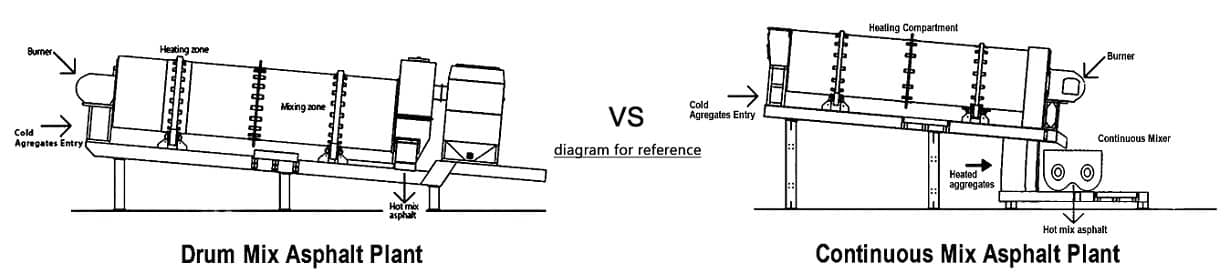

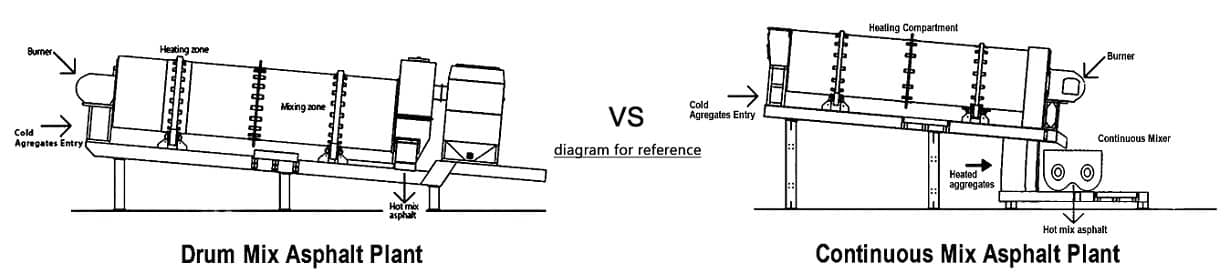

1.Drum mix asphalt plant install burner at the front end of drum, in which the aggregates migrate away from the burner flame in parallel flow direction, and the heated aggregates are mixed with bitumen at the other end of the drum. Whereas, the aggregates, in continuous mix asphalt plant, move towards the burner flame in counter flow direction, since the burner is installed at the back end of drum.

2.The drum of drum mix asphalt plant plays two roles in operation, drying and mixing. That means the materials come out of drum would be the finished production. However, the drum of continuous mix asphalt plant is only to dry and heat the aggregates, and the materials come out of drum have to be mixed by continuous mixer till to be the finished production.

3.The aggregates heated in the drum of drum mix asphalt plant follow drum to rotate and fall off by gravity, to contact with spraying bitumen and complete the mixing in drum’s rotation. As for the continuous mix asphalt plant, aggregates are heated to set temperature in drying drum, and then conveyed to continuous mixer with horizontal twin shafts, where hot aggregates would be mixed together with spraying bitumen, filler and other additive agents according to construction requirements till be mixed homogenously.

As above, counter flow structure design minimizes the moisture content in aggregates, and gives much more time to aggregates for drying and heating, which makes the continuous mix asphalt plant better heating efficiency. Additionally, continuous mix asphalt plant adopts forced mixing through strong power twin shafts. The various materials have sufficient contact with each other and could be mixed much more homogenous, and bitumen disperses among the materials completely to form better binding. Thus, it has higher mixing efficiency as well as better finished production performance.