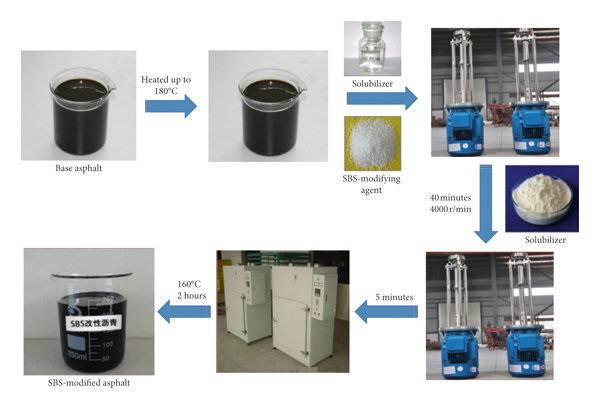

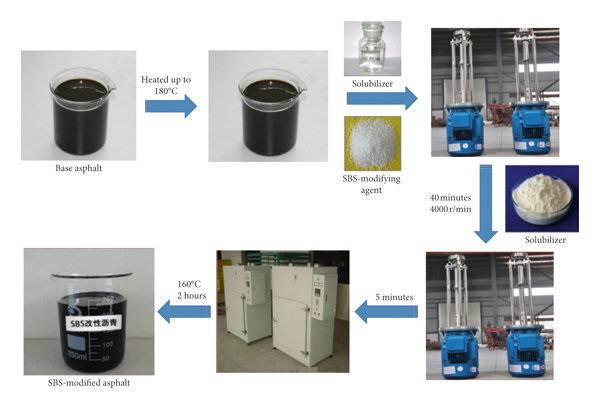

Use SBS as the main material to screen suitable compatibilizers and their formulas. Use an ordinary mixer to add a certain proportion of masterbatch to the reactor, heat and mix it with various matrix bitumens at about 160°C, and make the masterbatch through a granulation process.

Since polymer-modified bitumen requires the use of special equipment such as large colloid mills for processing, and only polymers are used to blend modified bitumen, it is mainly a simple physical blend, and there is no chemical bonding between the polymer modifier and the matrix bitumen. The stability of the mixed system is poor, and the compounding technology of SBS and matching compatibilizer to make SBS modified bitumen masterbatch improves the viscosity flow behavior of a single SBS modifier and reduces the temperature of the viscosity flow zone of the masterbatch. , the blending temperature is reduced from 180~190℃ to 160℃, and the use of conventional mixing equipment can meet the uniform dispersion and mixing of polymer and bitumen, thereby reducing the production rigor and saving production costs.

Refined styrene + refined solution + refined butadiene + antioxidant → polymerization → reaction blending → post-processing, packaging

Albanian

Albanian  Russian

Russian  Arabic

Arabic  Amharic

Amharic  Azerbaijani

Azerbaijani  Irish

Irish  Estonian

Estonian  Odia (Oriya)

Odia (Oriya)  Basque

Basque  Belarusian

Belarusian  Bulgarian

Bulgarian  Icelandic

Icelandic  Polish

Polish  Bosnian

Bosnian  Persian

Persian  Afrikaans

Afrikaans  Tatar

Tatar  Danish

Danish  German

German  French

French  Filipino

Filipino  Finnish

Finnish  Frisian

Frisian  Khmer

Khmer  Georgian

Georgian  Gujarati

Gujarati  Kazakh

Kazakh  Haitian Creole

Haitian Creole  Korean

Korean  Hausa

Hausa  Dutch

Dutch  Kyrgyz

Kyrgyz  Galician

Galician  Catalan

Catalan  Czech

Czech  Kannada

Kannada  Corsican

Corsican  Croatian

Croatian  Kurdish (Kurmanji)

Kurdish (Kurmanji)  Latin

Latin  Latvian

Latvian  Lao

Lao  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Kinyarwanda

Kinyarwanda  Romanian

Romanian  Malagasy

Malagasy  Maltese

Maltese  Marathi

Marathi  Malayalam

Malayalam  Malay

Malay  Macedonian

Macedonian  Maori

Maori  Mongolian

Mongolian  Bengali

Bengali  Myanmar (Burmese)

Myanmar (Burmese)  Hmong

Hmong  Xhosa

Xhosa  Zulu

Zulu  Nepali

Nepali  Norwegian

Norwegian  Punjabi

Punjabi  Portuguese

Portuguese  Pashto

Pashto  Chichewa

Chichewa  Japanese

Japanese  Swedish

Swedish  Samoan

Samoan  Serbian

Serbian  Sesotho

Sesotho  Sinhala

Sinhala  Esperanto

Esperanto  Slovak

Slovak  Slovenian

Slovenian  Swahili

Swahili  Scots Gaelic

Scots Gaelic  Cebuano

Cebuano  Somali

Somali  Tajik

Tajik  Telugu

Telugu  Tamil

Tamil  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Welsh

Welsh  Uyghur

Uyghur  Urdu

Urdu  Ukrainian

Ukrainian  Uzbek

Uzbek  Spanish

Spanish  Hebrew

Hebrew  Greek

Greek  Hawaiian

Hawaiian  Sindhi

Sindhi  Hungarian

Hungarian  Shona

Shona  Armenian

Armenian  Igbo

Igbo  Italian

Italian  Yiddish

Yiddish  Hindi

Hindi  Sundanese

Sundanese  Indonesian

Indonesian  Javanese

Javanese  Yoruba

Yoruba  Vietnamese

Vietnamese  Hebrew

Hebrew  Chinese (Simplified)

Chinese (Simplified)